Your Ultimate Guide to Industrial Ice Makers at Manufacturing Plants and Distribution Warehouses

The manufacturing and distribution industries have high ice demands, and need industrial ice makers that works as hard as their employees. Whether you use ice to keep your workforce refreshed or to keep products cool during long deliveries, an industrial ice machine is the most cost-effective solution. To help you find the perfect ice machine for your business, we created this handy guide to industrial ice makers.

Need help choosing the right industrial ice maker? Want to get your next ice machine through our all-inclusive subscription?

Call us today!

(327-9423)

Click a Section Below to Get Started

What Types of Ice Makers Are There for the Manufacturing Industry?

The manufacturing and distribution industries use ice for many reasons. Whether they need a large industrial ice machine for deliveries or a small countertop ice maker for breakrooms, there is an industrial ice cube maker machine for every need. Commercial ice makers come in all shapes, sizes, and styles. Below are some of the types of ice makers for your industry:

How Do I Select the Right Type of Ice Cube?

The shape of an ice cube is not just aesthetic. Each ice shape provides a different business need. Choosing the right type of ice can help to elevate your drinks, treat ailments, or even save you money.

How Much Ice Do I Need for My Distribution Warehouse or Manufacturing Plant?

Large warehouses and distribution plants need a high-volume industrial ice machine to cover their ice needs. They also need their ice machine to stay running through the toughest conditions. There are a few factors to consider when sizing an industrial ice maker for your business.

Daily Ice Usage/Amount of Staff

The first step to sizing an industrial ice machine is to find out how much ice your workforce goes through in a day. Warehouses can get hot, and your workforce needs ice to stay refreshed and productive. If you have staff that needs ice for long deliveries, consider how much ice they take during each trip. We've put together this handy Ice Machine Estimator to help you determine your daily ice needs.

What’s the Best Industrial Ice Maker Condenser for My Environment?

Your ice machine’s condenser is one of its most vital components. It cools down refrigerant to use in the ice-making process but also gives off a lot of heat. That heat needs to be released, or it will overwork the machine. There are three condenser options for industrial ice makers, and each has its pros and cons.

Air Cooled Condensers

Air cooled ice machines are the most popular and cost-effective cooling system for ice machines. A fan helps cool condenser coils and pushes hot air into the surrounding environment where it can disperse. These systems require at least a foot of space on all sides of the ice machine (including the top) to allow air to escape. The room your install your ice maker should be large enough for the air to move freely. Areas with limited ventilation cause ice machines to overheat, lowering ice production.

View Our Air Cooled Ice Machines

What are the Installation Requirements for Industrial Ice Making Equipment?

Manufacturing and distribution plants can be challenging environments for industrial ice makers. Ice machines need to stay cool and have plenty of ventilation to keep up with your workforce’s ice needs. Here are main things you need to provide.

Space and Temperature

Ice machines work best in 70-degree temperatures. As the heat rises, the ice machine’s production rate lowers, which means less ice. If the temperature reaches into the 100s, an ice machine can breakdown, leading to expensive repairs. Make sure your industrial ice maker is in a temperature-controlled environment with at least a foot of space on all sides of the unit.

Electricity

Larger industrial ice machines require more voltage to run. Most ice machines only need a 110v outlet to run. A large ice maker that produces over 800 lbs of ice a day needs a 220v outlet. There are also different amperage needs so check your model's requirements. If your workplace doesn’t have the proper outlet, you’ll need to call an electrician to install one.

Water

Your water line needs to deliver the proper flow rate of water to your ice machine for it to function correctly. Low water flow leads to smaller, malformed ice cubes and less ice overall. Depending on the model, industrial ice making machines require between 3-5 gallons a minute. If your water line can’t provide the proper flow rate, you’ll need to call a plumber to install one that does.

Drainage

As ice melts, an ice machine needs to flush excess water out of the ice bin. Most ice machines flush water into a floor drain, but there are other drainage options that can work as well. Countertop ice makers commonly use a wall drain. You may need to call a plumber to install the right drainage option for your facility.

We’ve serviced over 10,000 ice machines across the country. No matter the challenge, we know exactly how to keep your ice machine running smoothly. Our pre-installation checklist shows you what you need to provide to install an ice machine in your business. If you have a challenging environment, give us a call and we'll help you find a solution.

What are Some Environmental Factors I Want to Avoid?

There are a few factors that can affect your ice production. These factors can overwork your industrial ice maker, which will eventually lead to expensive repairs if they are left unchecked. Here are the factors you should look out for:

Heat

As the temperature of your ambient air and water increase, your machine will produce less ice. When hot air or water enters your ice machine, it will overheat the system. This forces the ice machine to work harder to produce ice.

Cold

The cold can also affect your ice machine. If you install your machine in freezing temperatures, water will freeze in distribution tubes. Frozen water lines restrict water flow, which can stop your ice machine from making ice.

Low Ventilation

Air cooled ice machines emit hot air, so they need ventilation so the heat can disperse. Limited ventilation will cause air to re-enter the ice machine and overheat the system. An overly hot machine will produce less ice.

Dust and Dirt

Dust and dirt are common in factories and plants. If they enter your ice machine, dirt and dust will cling to vital components, and overwork the unit. A dirty ice machine will produce less ice and can lead to expensive ice machine repairs.

Hard Water

Hard water contains minerals that combine to form scale. Scale clings to components in your ice machine, causing them to freeze up and stop working. Eventually, these components break and lead to expensive repairs.

How Do I Keep My Industrial Ice Maker Clean and Sanitary?

Industrial Ice machines require cleaning to keep ice safe and protect staff from infection. Scale from hard water can cause damage to the unit. It’s important to make sure your staff has a routine ice machine cleaning schedule that includes ice machine care. Proper water filtration will help to eliminate scale. Also, ice machines require at least 2 professional cleanings per year to stay efficient.

How Much Does It Cost to Own an Industrial Ice Machine?

A high-volume industrial ice maker can cost up to $10,000. Smaller ice dispensers for your front office can cost around $1,500. There are also hidden costs associated with owning an ice machine as well. Preventive maintenance, professional cleaning, and routine repairs are all necessary to keep your ice maker running efficiently.

Maintenance

Ice machine preventive maintenance allows technicians to optimize your machine and identify potential problems. This keeps your ice machine running in peak performance and helps you avoid expensive repair costs. Ice machine manufacturers recommend two visits a year from an experienced ice machine technician. The average preventive maintenance costs around $300 per visit.

Professional Cleaning

Routine cleaning from your staff is necessary, but professional cleaning is also needed to get to those hard to reach areas. A technician will take the industrial ice machine apart and clean it using strong acid-based cleaners to rid the unit of mold and scale. Manufacturers recommend getting two professional cleanings per year, more if your ice machine is in a particularly dusty area. Cleanings can cost around $250 per visit.

Breakdowns

The cost of an ice machine repair depends on the extent of the problem. Repairs can cost between a few hundred dollars to a few thousand. Here are some examples of some common ice machine repairs and their estimated costs:

- Hot Gas Valve Replacement - $600

- Expansion Valve - $600

- Compressor Repair - $1500

- Evaporator Repair - $2500

If your facility depends on ice, a machine breakdown can severely hurt business, forcing you to spend hundreds on replacement ice. 1000 lbs of ice costs around $225.

Get a High-Quality Industrial Ice Maker Without Spending a Fortune

Even the best commercial ice equipment isn't as tough as it looks. Industrial ice machines require optimal temperatures and routine maintenance to stay in top condition and produce the maximum amount of ice. Professional cleaning is also required if you want your ice supply to stay consumer-safe.

An Easy Ice subscription gives you a top-rated ice machine, biannual preventive maintenance, professional cleanings, and all repairs for one low, monthly payment! Say good-bye to ongoing ice machine service bills and the hassle of scheduling maintenance appointments every six months or more. With an Easy Ice subscription, you'll save money and eliminate the responsibility of ice maker care from your to-do list.

Ready for a hassle-free ice machine experience? Want to save money upfront and over time on your next industrial ice maker?

Try our all-inclusive ice machine subscription.

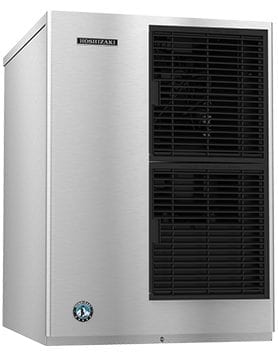

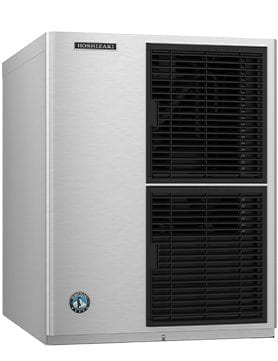

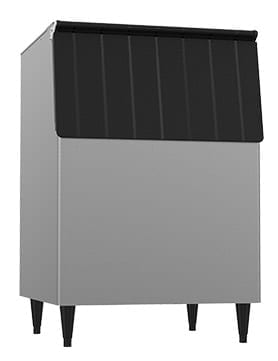

Modular Ice Machines

Modular Ice Machines